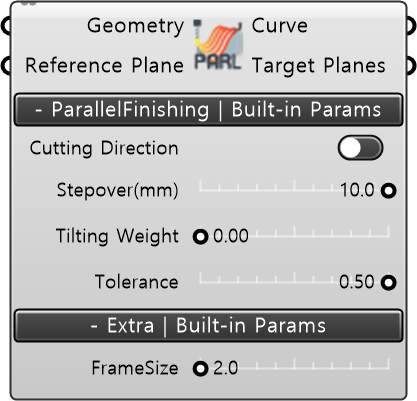

ParallelFinishing

🌐 KR

Description

- This is a cutting toolpath component for the second milling step.

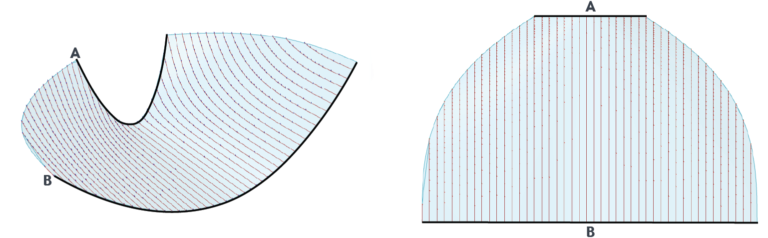

- It divides the curves between parallel curves of varying lengths into equal length segments in the cutting direction as shown below.

Input

- Geometry: Input the Geometry parameter of Mesh or Surface.

- Reference Plane : Input the base plane for Target Orientation when Tilting weight=0.

Built-in Param | Basic Params

- Cutting Direction [Boolean] : Select the direction, U(False) / V(True).

- Stepover : Determines the amount of material removed horizontally in a single pass. By default, it should be less than or equal to half the diameter of the end mill. A smaller value allows for finer finishing. (Stepover <= End Mill Diameter * 1/2)

- Tilting Weight : Weight of the Target Tilting, ranging from 0.0 to 1.0. When closer to 0, it aligns with the BasePlane’s normal; when closer to 1, it aligns with the Surface’s normal, tilting the Target Plane accordingly.

- Tolerance : Toolpath resolution.

Output

- Curve : Outputs the curves of the finishing layer.

- Target Plane: Outputs the index values of the planes as a DataTree.