ObjRoughing

🌐 KR

Description

- Component providing cutting toolpaths for the first milling stage.

Input

- Geometry: Input the volume to be roughed out as a solid (Brep) or mesh (Mesh) type.

- Reference Plane : Input the reference plane that determines the end mill entry direction (Contour direction), target orientation, starting position of the toolpath, collision avoidance height for machining surfaces, etc.

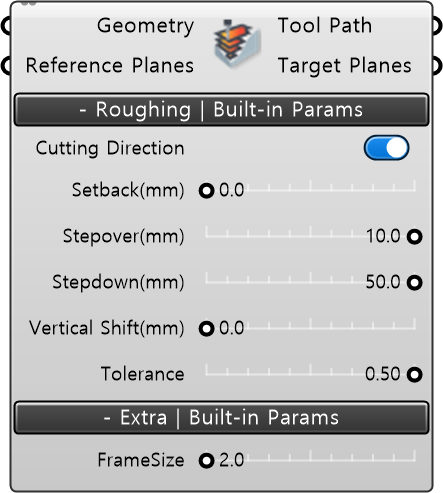

Built-in Param | Roughing

- Cutting Direction [Boolean]: Selects the upward (True) or downward (False) cutting direction.

- Setback : Determines the extent to which the roughing toolpath is offset from the final machined surface. It must be greater than half the diameter of the end mill. (Setback > End mill diameter * 1/2)

- Stepover: Specifies the amount of horizontal material removed in one pass, calculated as less than half the diameter of the end mill. (Stepover <= End mill diameter * 1/2)

- Stepdown: Sets the vertical depth of each drilling pass, calculated as less than half the flute length of the end mill. (Stepdown <= End mill flute length * 1/2)

- Shift: Shifts the entire vertical direction of the Stepdown layer.

- Tolerance: Determines the resolution of the toolpath.

Output

- Targets Plane : Converts the results of movement and avoidance paths into a DataTree with even branches.

- ToolPath : Converts the results of movement and avoidance paths into a DataTree with even branches.